Even with the deteriorated optics, the 1.2m has been oversubscribed significantly. A properly functioning telescope will have much higher sensitivity due to better image quality, higher reflectivity, and considerably lower scattering. This increased sensitivity together with upcoming support for automated scheduling and observing will open attractive new opportunities.

Current Science: examples

- Planets

Lately, the telescope has had its highest production in high-accuracy photometry of exoplanet transits at optical wavelengths, to confirm detections by HATnet and MEarth at FLWO, or by projects at other observatories. The majority of the publications based on 1.2m data are related to exoplanets. - Supernovae

The CFA Supernova Group has obtained multiband photometry of several hundred supernovae with the 1.2m. They acquired the CfA3 SN Ia sample in the period 2001-2008. CfA3 comprises over 11,500 observations. Most recently, this sample has yielded improved constraints on the dark energy equation of state parameter, w (Hicken et al. 2009, ApJ 700, 1097). - Other Projects

In addition to transient observations, the telescope is used for a wide variety of studies, as illustrated by the titles of proposals with time awarded in the September-December 2009 trimester: "Revealing dust formation in naked supernovae with FLWO 1.2m," "Exotic explosions and eruptions: new transient phase-space with Pan-STARRS," "Identifying and monitoring GRB afterglows with the FLWO 1.2m," "Monitoring lensed quasars: microlensing and time delays," "Periodic photometric variability in rapidly rotating ultra cool dwarfs," "Supernova light curves," "Optical photometry of the Orion cloud complex," and "Young AB star disks in Cygnus X."

Future Science

-

Time-domain studies have played

a major role throughout the history of the CfA, including the

discovery and classification of various types of variable stars,

gravitational lensing and microlensing, exoplanet transits, and SNe.

However, it is only recently that all-sky

time-domain surveys at optical and radio wavelengths are coming

online, with the goal of characterizing variable and transient objects

over a new range of timescales and luminosities. The Panoramic Survey

Telescope and Rapid Response System (Pan-STARRS) and the Murchison

Widefield Array (MWA) -- both of which include the CfA as a major

partner -- will usher in a new phase of time-domain astronomy. The

scientific body at the CfA is well positioned for this opportunity,

hosting astronomers with a wide range of interests in transient and

variable objects.

Facilities like Pan-STARRS and MWA are capable of finding an unprecedented number of diverse transient or variable sources (so called "discovery machines"). However, the actual classification and physical understanding of these objects require detailed follow-up studies. In this context, the FLWO 1.2m plays a crucial role with its ability to respond promptly to alerts of new transients discovered by Pan-STARRS, MWA, and other facilities including X-ray and gamma-ray satellites, and uniquely enabling immediate follow-up observations. Indeed, with the planned automation of the telescope in the next year, the FLWO 1.2m will respond to transient alerts with minimal human intervention.

Perhaps more importantly, we envision the FLWO 1.2m as the cornerstone in the network of follow-up facilities that will be used to chase newly discovered tranisent and variable sources. Through prompt multi-band optical imaging, the most intriguing transients can be intelligently identified based on their spectral and/or temporal evolution and passed on to larger CfA facilities for more detailed follow-up. For example, subsequent observations will include those from (i) the FLWO 1.3m automated PAIRITEL to constrain the near-IR emission component, (ii) the FLWO 1.5m and MMT to provide spectroscopic diagnostics and redshifts for the new transients, and (iii) Magellan observations to trace the evolution into the late phase once the transients have become too faint for the smaller CfA facilities. This leveraged approach is essential given the expected large numbers and diverse types of new transients that Pan-STARRS and MWA will reveal, as well as the competition from other institutions.

Replacement Plans

The telescope provides stellar images of about 2.5 arcsec FWHM, while a properly functioning mirror will provide seeing-limited images of about 1 arcsec FWHM. Better images will yield greater sensitivity for photometry, and allow much improved star/galaxy or star/star separations for SNe, GRBs, and gravitational lenses.

The replacement primary mirror will have an optical design identical to that of the current primary mirror, and tight optical performance specifications to ensure image quality limited only by site seeing. Construction of an identical mirror will allow us to continue operations until the replacement is ready. Once it is ready, we will mount it in the existing primary cell, and proceed with observations with the existing telescope.

The timescale for the casting and polishing of the primar mirror is 2 years starting in 2009. We purchased the glass and refractory materials for the casting with IR&D funding in FY09. We divided the rest of the project into 2 phases. In Phase 1, SOML is casting the mirror with FY10 IR&D funding (PI Falco, Co-Is Fabricant, Soderberg and Berger). In Phase 2, SOML will polish the mirror, with an estimated delivery by August 2011. We obtained FY11 IR&D funding for Phase 2.

Updates

The project is proceeding apace. The picture gallery below shows the progress.

Pre-fire was planned for the week of Aug 23. The casting was planned to start Tuesday Sept 7 with high temperature occurring on the morning of Sept 10. This plan was contingent on the results of the pre-fire inspection.

The pre-fire went off without a hitch. EF visited SOML on Aug 31, and saw the mold as it was being cleaned up and readied for loading the glass. A final inspection revealed the mold is in excellent shape, and ready.

High temperature (about 1155C) was reached as planned on 09/10. At 11:30am a FLWO contingent (Falco, Peters, Groner, Esquerdo and Brocious) visited SOML to view the furnace. SOML personnel present were Jeff Kingsley, Randy Lutz, Steve Warren, Mario Rascon, Buddy Martin. The mirror was starting to cool down, with the furnace rotating slowly (about 2 rpm) to ensure even cooling. It was impossible to discern any structure inside the furnace because of the extreme glow. Here is a view from the sole camera available for the small size (relative to the furnace) of the 1.2m mirror:

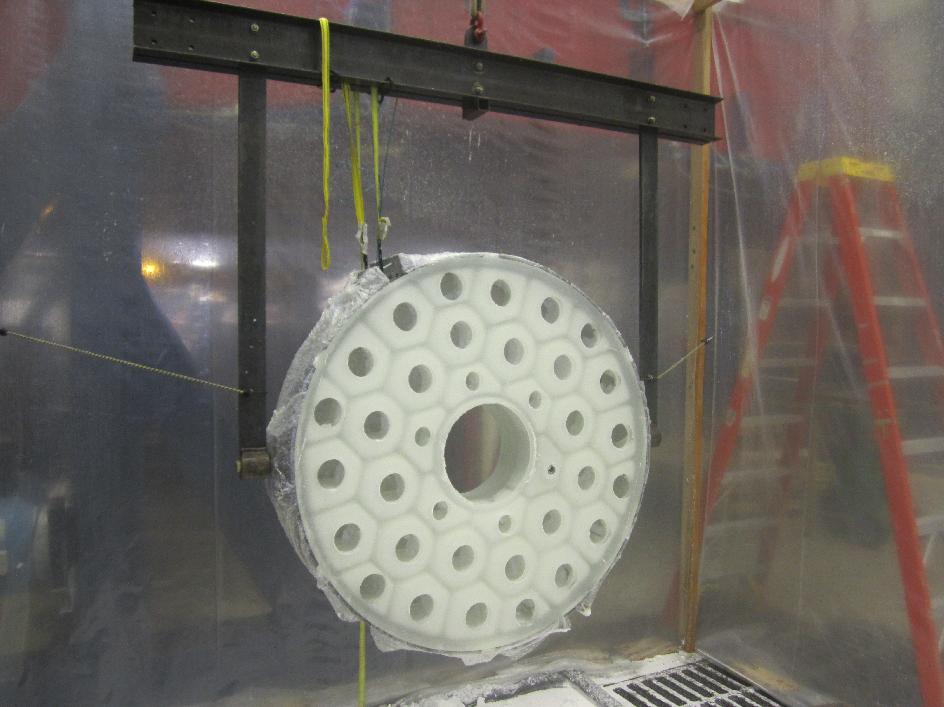

The mirror blank hangs for inspection after cleaning; back side view, note the clarity of the glass, 12 Nov 2010:

The SOML budgetary estimate and technical specifications and requirements for polishing the mirror are available here (pdf). The SAO Purchase Order for the polishing of the mirror was submitted to UofA on 01/31/11. It was signed by all parties in early March 2011. SOML is starting the figuring in collaboration with the College of Optical Sciences (COS) at UofA.

The mirror is now at COS, where the backplate generation started the week of 04/11/11. The last phase of backplate grinding is underway, with polishing set to start the week of 05/02/11.

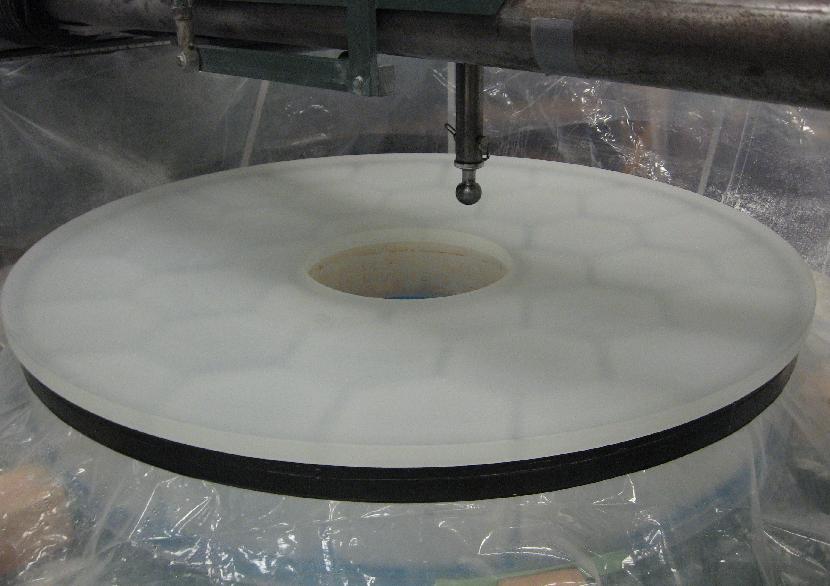

The backplate generation was completed on 05/06/11:

Generation of the frontplate began on 05/09/11 and was completed by 06/07/11:

The next step is the loose abrasive grinding of the frontplate, starting the week of 06/27/11.

As of 09/29/11, the completion of the mirror had slipped to the end of December 2011, due to a failure in the polishing machine at COS. The machine is now repaired, tested and operational.

The mirror is now generated and ground to the "best fit sphere" as described here (pdf, 2.5MB).

As of January 2012, the completion of the mirror had been extended

to May 2012. The causes of this delay are the inefficiency of the original

setup and the personnel resources that were available. Currently, these

have been increased and the process has been streamlined significantly so

it is much more efficient. There is light at the end of the tunnel.

The latest report from SOML

shows that the aspherizing is progressing well, as

described

here

(pdf, 280KB).

As of April 2012, the completion of the mirror had been extended again,

to June 2012.

The latest report from SOML

shows that the aspherizing is complete and polishing has started, as

described

here

(pdf, 917KB).

July 2013

After several delays from problems with the polishing equipment at COS, we have determined that the mirror is in full compliance with our requirements. The document that demonstrates compliance is here (pdf, 1.4MB).

The mirror is scheduled for aluminization at the "Sunnyside" UA facility in Tucson on 07/31/13. We will swap it in during the first week or so of the August 2013 shutdown.

Picture Gallery for the Project