FLWO 48" INCH TELESCOPE REALUMINIZING PROCEDURE

Updated 08/23/17 EF

Items needed:

Notify SO and confirm that schedule is OK.

Sign Agreement and forward to SO.

Issue PO for the work.

Aluminum mirror lifting device

Yellow bar

Yellow hoisting tool

Yellow 3-legged cart

Mirror box and lid

Plastic tarps to cover mirror box and cell in case of rain

Foam mirror cover

Crown forklift

Pallet jack

2 short lifting straps

Mechanical Hoist

Removal Procedure

-

Remove Dec primary bearing cover (East fork).

-

Move telescope in DEC only, South to ~0 DEC so that access to the

Eastern cell bolts (particularly the southernmost of the three) can be

had. Loosen the two bolts. This is done because these bolts can't be

fully accessed when telescope is at zenith. Don't even try.

Even more complicated if the topbox has been removed.

On 07/25/12,

we had the topbox off after the rain event on Sunday 07/15/12

(see Changelog). Ted managed to remove the middle bolt with the

telescope pinned. We managed to slowly and

carefully move the telescope after

removing the DEC pin using ropes and pulleys tied to the

OSS on the N and S with Wayne, Ted and

Emilio handling the ropes. The remaining problem bolt on the N end

of the trio finally became accessible and was removed.

-

Return telescope to zenith.

-

Pin telescope at zenith.

-

Bring secondary mirror all the way toward primary (larger numbers

for the hexapod) with the telescope control program. From code

or hexapod PC:

Range -24 to +24 mm, so move to 23.0

-

If filter wheel assembly requires work: remove all filters

from top box, using TCS. Then, move all guide

probe motors to 0 using TCS and disconnect motor power.

-

Power off topbox and Lakeshore. Remove instrument and cabling

carefully, to avoid straining any wires. Disconnect cabling to

topbox.

-

Remove any interfering wiring from North plate electronics.

-

While standing on closed mirror doors, remove secondary baffle, 4

3/32" Phillips screws.

-

Remove secondary mirror. This is a

two-person job on top of the telescope!

First, remove felt on center of secondary.

Second, insert all-thread safety bar through the center of the support

and secure it with the nut (which should be on the bar when in

storage) below the secondary. Third, remove the 4 allen screws

(3/16") that hold

the mirror mushroom against the hexapod; the mirror is held by the bar at

that point. Fourth, one person should hold the mirror by the collar

while the other loosens the nut on the bar, and then carefully lower

it and hand it to a third person at the top of the yellow ladder.

-

After the secondary is moved to the hole in the center of the wooden

(dewar) cart with the mirror facing up, remove secondary mirror mount

by removing the 6 allen screws (3/32", of slightly different lengths)

that hold the washers (spring and teflon) on at the front.

From below the hole, remove the 3 allen

screws (9/64") that tie the holding fixture to the metal puck on the

back of the mirror. No need to remove the collar!

Then, gently twist the "mushroom" with respect to

the mount until it is twisted off. It can take some doing as it's a VERY

snug fit. There are 2 o-rings on the shaft, 1" OD, that may break during

removal. We are ordering some of these 8/17/17.

-

Place secondary mirror in its box for shipping (replacing the second

secondary mirror, which is stored on a shelf, in the cabinet

inside the clean room).

-

Remove topbox. Raise the lifting table to the level of the topbox,

and then remove the bolts that hold the spacer plate onto the cell.

-

Remove the primary baffle. It has a ring where the mirror covers rest,

so it is best to do it at this point, not earlier.

-

Remove cell cover plates.

-

Raise the 3 axial hardpoints. Give each one 1.5 turns. At

that point, the primary will be

fully supported by the hardpoints. This procedure

deactivates the 27 axial actuators, which need not be touched so

at re-assembly, the primary will return to its position before removal.

-

Install yellow bar at top ring using two short yellow straps around

the top ring and around the OSS arms.

Bar should be aligned north/south. One person should

remain on top of the primary covers to work with the hoist.

-

Install mechanical chain hoist. The chain is too long and heavy.

Larry will shorten the chain (8/1/17).

-

Bring chain down through the Cass hole, and hook it onto the yellow

hoisting tool (flange with stem, aka mushroom).

-

Raise hoisting tool to bottom of mirror cell. Bolt tool to cell (2

bolts will do). Tighten up chain.

-

Loosen and remove cell bolts. Note that the northernmost bolt on the East

side is shorter than the others. The cell is made of 1018 HRS; it

weighs about 1040lb.

-

Lower cell onto the 3-legged cart, until it rests on the

legs but without engaging the legs in the holes to lift the mirror. Be

careful of cell/telescope clearances.

Mind the gap! Between the dial indicator on the NE side and the E

side cover. It is all too easy to bend the indicator and make it useless.

-

Working above the mirror, remove the earthquake/baffle ring.

Remove the piece with angled ends first.

-

Remove the radial dial indicators (these are labeled, keyed to

the same labels on the cell). If not exactly at 0, reset them all to 0 to

simplify centering during reinstallation. Make sure to leave the indicators

undisturbed, so they will read useful numbers at reinstallation.

-

Disengage the radial actuators from the invar radial load spreader

bars. As of August 2013, we have new spreader bars (made at UA's

University Research Instrumentation Center, URIC) on the new mirror.

Posts were epoxied to the glass with Hysol 9313 (mounted at COS

following Joe Zajac's instructions).

They are much sturdier than the old ones, but a bump could pry them off.

In August 2014, we easily removed the pins that link the

actuators to the bars, after removing the cotters at the ends of the

pins.

- Remove the radial actuators.

Unscrew only the 4 hex (3/32) screws so the actuators

will maintain their position relative to the cell at reinstallation.

-

Back off the radial hardpoints until you see about a 2mm clearance.

-

Lift the cell off the 3-legged cart a few inches, and align the legs with

the holes in the cell that will permit contact with the mirror.

Larry replaced all 3 wheels of the cart with wheels that swivel.

Much better!

-

Lower the cell onto the cart, until it makes contact with the glass.

This is a good time to pop some of

the 3 delrin 1/2

pucks

off the bottom of the cell, working from below

the cell. Only pop the 3 1/2 pucks that let temp sensor wires through.

Pull through the temp sensor wires, one connector at a time.

At that point, the wires should rest on the cell so as not to impede

the removal of the primary.

-

Slowly lower the cell until the mirror is about

2 inches above the cell.

Always watch the temp sensor wires so they don't get

tangled, pulled, or pinched.

-

Install the aluminum triangular mirror lifting fixture using

3 straps from the eyehooks to the hook on the chain. Lift the mirror

off the 3-legged cart.

-

Remove the radial load spreader bars from the mirror (these

are numbered and keyed to the same numbers on the mirror).

-

Roll the cell out of the way. Take care not to run a wheel over a trench

where the floor is weak.

-

Open the box, remove top foam padding, and use the pallet jack to roll

it under the mirror.

-

Lower the mirror into the box.

-

Remove the lifting fixture

-

Put the top on the box.

-

The mirror box is 64"x64"x 19". The 19" includes the blocks on the

bottom to provide fork lift access. The box weighs 550 lb. The new

mirror weighs 430 lb.

-

Load the mirror box in the flat bed truck. The Crown 15M hand forklift

will lift 1500 lb at 20" . There is a chance that the mirror box could

tip forward, therefore, the mirror box should be attached to the fork lift

with a harness. The height of the loading dock is 25" from the drive. Lady's

bed is 40" from the drive. The front part of the mirror box is first set

in the truck and then the mirror box is pushed in with the fork lift and

people. This works better than it sounds.

-

No special padding is required. Drive flat bed truck to Sunnyside.

Reinstallation Procedure

In general, the reverse of removal. The following notes may be useful.

When lifting the box from the truck and moving into the dome, be certain

that the 4x4's on the box clear the front fork wheels as well as the forks.

-

If the secondary was aluminized, reverse the disassembly procedure.

To re-install the secondary mirror mount,

first place the teflon washer over the hole.

Then, screw in the 6 allen screws (3/32", of slightly different lengths)

that hold the washers (spring and teflon). Start one of the longer

screws first, to locate the hole for the screw. Then, proceed with

the other screws.

- If some of the temperature sensors fell out, be ready to have

fun with epoxy (Omegabond 101, in the fridge). Lower the mirror on 3

3-ft 4x4s (in the chamber). Leave the mirror hanging on the triangular

lifting tool, apply partial weight on the 4x4s. Proceed to gluing.

The extensible back scratchers that prop up the

epoxied sensors are stored in the red tool box,

top section, in the shop. Working from below,

apply Omegabond to the each sensor, and

use the back scratchers to push each sensor against the glass, inside

the honeycomb cells.

Use one small section of 4x4 and a wedge to help stand up the back scratchers.

The Omegabond needs to cure overnight.

We will look into using thermally conductive tape next time.

- Mount spreader bars on mirror before installing the mirror in

cell. As of August 2013, the new posts are symmetrically arranged

on the new mirror,

so there is no need to offset the bars as for the old mirror.

The spreader bars are mounted

to the posts with, starting at the post, a plastic washer, 2 cupped

bellevilles, the bar, 2 cupped bellevilles, a nut. Per DFM

instructions on 08/07/13.

- Radial dial indicators should already be

out (see removal procedure above). If not, remove them now.

- Lift the mirror off the 4x4s. Roll the cell underneath the mirror.

Lower the mirror until it rests on the nylon pads of the 3-legged tool.

Carefully feed the temp sensor wires through cell holes (3 with 1/2 pucks,

one just a vent hole),

and reinstall the 1/2 pucks (push them down with some

force). Use tie wraps to bundle the wires near the mirror, and attach

bundles to the cell with tie wraps through the pads on the cell.

- Get rotation correct before lowering mirror all the way into cell. Now

lower mirror onto axial hardpoints, which were raised 1.5

turns during removal.

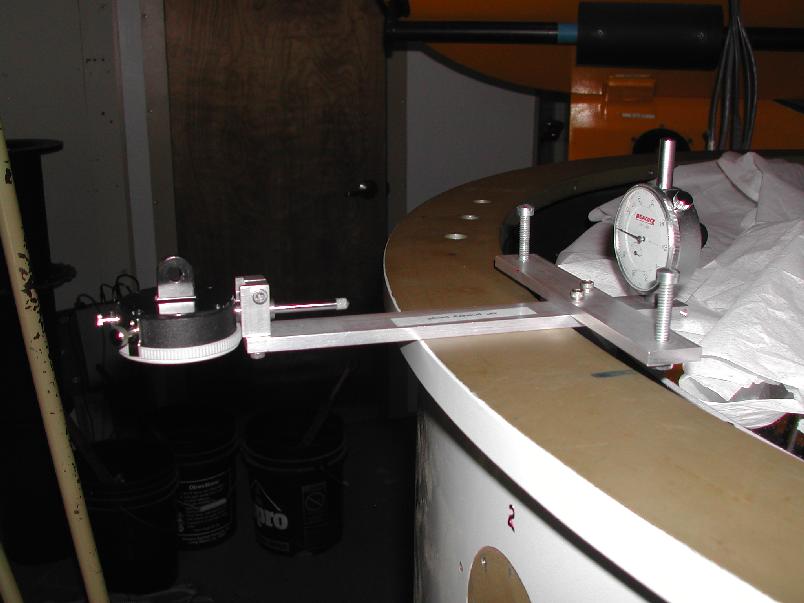

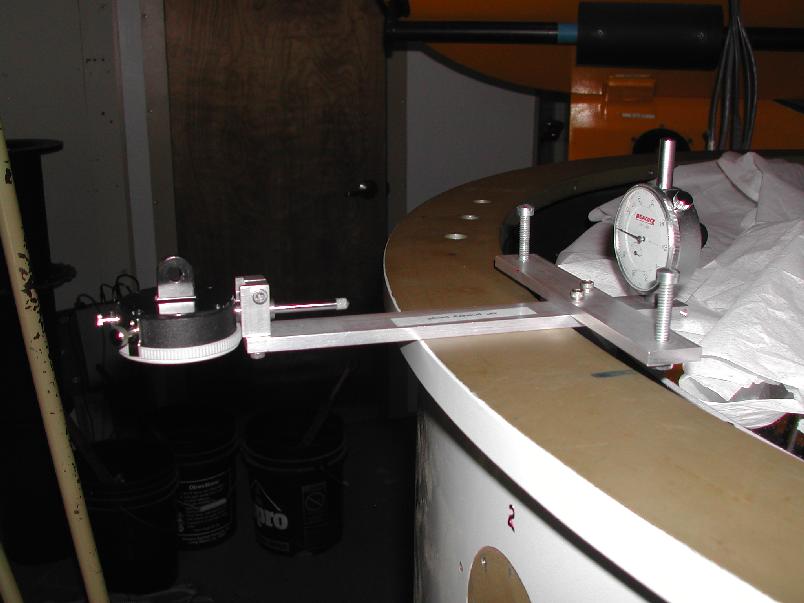

RH made a jig (see pics

below) that allows mounting a dial indicator at either end. It's stored

in the shop, in the top section of the red tool box.

If necessary, use it to measure

the separation between the outer circumference of the

cell flange and the side of the mirror or the

separation between the edge of the mirror and the top of the

cell flange.

- Lift the mirror and cell at least 1ft higher than when

it was resting on the 3-legged tool for the load cell connector to

reach the socket in the cell. The primary should now rest on the axial

hardpoints giving load cell readings of around

120 lb. If lower than this, the mirror may be stuck on something.

- Lower the

axial hardpoints by removing the 1.5 turns described in the removal procedure.

The primary will then rest on both the axial hardpoints and

the nylon pads. Reset the axial

dial indicators.

- Height of mirror: Edge of mirror should be 1.25 inches below

cell mounting flange. Check (and re-check) level

from top surface using the RH jig.

- If they were disengaged, re-engage

axial actuators before doing final centering, to allow ease of motion.

- Move mirror radially using the radial hard points, monitor the

re-installed dial indicators for motion. Hard points are quite springy,

so some relaxation must occur before taking readings.

- Mount the 6 radial actuators. For these, the bearing that attaches to

each bar has two nuts. These must allow some play when attached to the bars.

- Remember to install short bolt rightmost (N) of the three

holes on the East side.

Only two bolts are installed on this side (middle and rightmost). Put these

two in with fingers first, then when telescope is movable, move telescope

far south so that a wrench may be used for final tightening.

-

Reinstallation of the secondary mirror is a

two-person job on top of the telescope! Plus a third person on the tall

yellow ladder. Reverse the removal procedure.

- Adjustment of the axial actuators is a many-iteration process. Monitor

the axial loads as you work around the counterweights. Start by lowering the

radial hardpoints until you are close to the final load on each hardpoint,

about 21 lb. The axial counterweights should move freely up when pushed,

about 1 inch until they hit the cell. Some of these may become pinned

to the cell. Ease these out by unscrewing the larger bolt at the pivot

end of each counterweight. If the bolt comes out, the pin will fall

through and the puck will end up lying on the cell. Most of the

pucks are inaccessible with the mirror in the cell. Once all the

axial counterweights are free to move, and the axial load cell readings

are about 21 lb, you are done. However, when the top box is mounted,

all these readings will change and will require re-adjustments. About

1/2 of the counterweighs are inacessible with the topbox mounted, and

only the S hardpoint hole is accessible.

Fun visual notes for the reinstallation:

RH jig in the mode used to measure the primary centering in the cell.

The cell flange OD is 58 inches (from

DFM drawing). The mirror is 48 inches, the difference

is 10 inches, so 5 inch for the spacing between the

outer edge of the flange and the mirror edge. The latest reading (9/17/15)

with the jig was 303 +- 3 x 0.001 inches (measured at 4

cardinal points), a relative number that

indicates centering good to +- 0.003 inches.

RH jig in the mode used to measure the primary centering in the cell.

The cell flange OD is 58 inches (from

DFM drawing). The mirror is 48 inches, the difference

is 10 inches, so 5 inch for the spacing between the

outer edge of the flange and the mirror edge. The latest reading (9/17/15)

with the jig was 303 +- 3 x 0.001 inches (measured at 4

cardinal points), a relative number that

indicates centering good to +- 0.003 inches.

RH jig in the mode to measure the primary depth in the cell.

Should be 1.25 in.

Reading out load cells with cell on 3-legged cart.

********************************

REALUMINIZATION 2004 (KPNO)

********************************

REINSTALLATION NOTES 2013(pdf scans)

REINSTALLATION NOTES 2014

REINSTALLATION NOTES 2015

REINSTALLATION NOTES 2017

RH jig in the mode used to measure the primary centering in the cell.

The cell flange OD is 58 inches (from

DFM drawing). The mirror is 48 inches, the difference

is 10 inches, so 5 inch for the spacing between the

outer edge of the flange and the mirror edge. The latest reading (9/17/15)

with the jig was 303 +- 3 x 0.001 inches (measured at 4

cardinal points), a relative number that

indicates centering good to +- 0.003 inches.

RH jig in the mode used to measure the primary centering in the cell.

The cell flange OD is 58 inches (from

DFM drawing). The mirror is 48 inches, the difference

is 10 inches, so 5 inch for the spacing between the

outer edge of the flange and the mirror edge. The latest reading (9/17/15)

with the jig was 303 +- 3 x 0.001 inches (measured at 4

cardinal points), a relative number that

indicates centering good to +- 0.003 inches.